Hot Distortion of Sand Cores during Casting

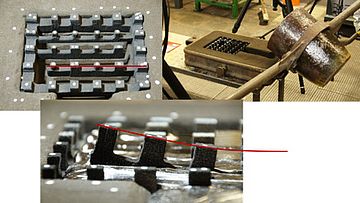

Dimensional tolerances in castings, especially for filigree shapes, are very dependent on the distortion of the sand cores used to form the casting contour during the casting process (Figure 1). Despite its importance for casting and component quality, up to now very little effort has been expended to truly understand the behaviour of these cores during casting. This situation is changing, especially due to the increasing interest in inorganic binders and the corresponding process changes resulting from a change in binder systems.

The objectives of this project are to gain a fundamental understanding of the distortion of sand cores and the most important factors which influence this distortion; casting process simulation will be used to predict core distortion in order to optimize the dimensional accuracy of cast components and minimize unavoidable distortion in the construction phase of core boxes in advance.

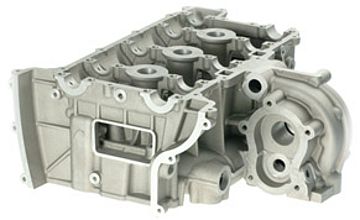

The behaviour of various sand/binder systems at room and elevated temperatures will be characterized (Figure 2). This involves both selecting appropriate experimental measurement methods as well as developing material models that allow the accurate prediction of core distortion. These models, together with measured material data, will be applied and validated through the investigation of the distortion of a demonstrator geometry (Figure 1). The use of project results on a cylinder head from series production with complex inside cores (Figure 3) is planned as a final step in the project.

The companies Nemak and MAGMA together with the Foundry Institute of the RWTH Aachen University form the project consortium.